| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Nozzle

Neck (Thickness and Reinforcement)

|

| |

|

| |

|

ASME BPVC

VIII-1-2015, UG-45 Nozzle Neck

Thickness and,

|

| |

|

UG-37

Reinforcement Required for Openings in Shells and Formed Heads

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

(Enter values in yellow cells for calculations and

in blue cells as information)

|

| |

|

ASME BPVC

VIII-1-2015, UG-45 Nozzle Neck

Thickness and,

|

|

|

|

|

|

|

|

|

|

|

|

Page

|

|

|

|

UG-37 Reinforcement

Required for Openings in Shells and Formed Heads

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Introduction

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

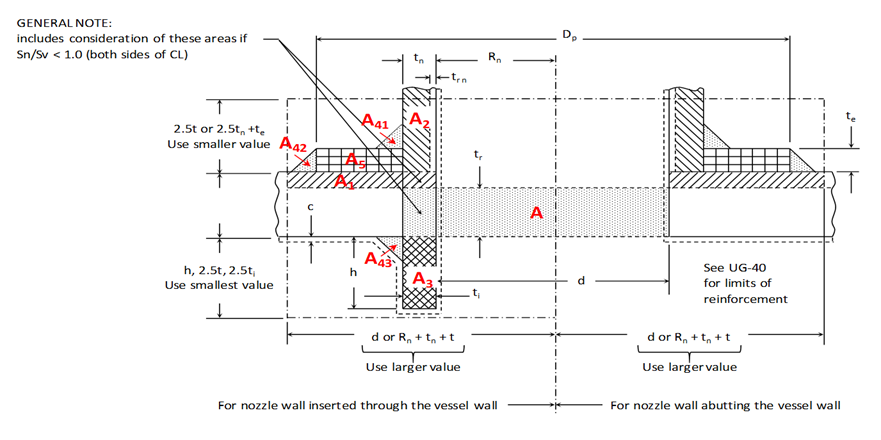

The

following calculation for minimum internally corroded radial nozzle neck

thickness and reinforcement is based on ASME VIII, Div 1, sections UG-37 and

UG-45. Data Input shall be in Page 2.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pictures / Sketch

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nozzle size (NPS):

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

Outside diameter of

reinforcing element, Dp:

|

|

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Summary

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nozzle welded on

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type of Head (If nozzle

is welded on Head)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum Limit of

Reinforcement (Parallel to vessel wall)

|

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

Maximum Limit of

Reinforcement (Normal to vessel wall outside)

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

Maximum Limit of

Reinforcement (Normal to vessel wall inside)

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

| |

|

|

Shell or Head Nominal

Thickness, ts or

th

|

|

|

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

| |

|

|

The minimum nozzle

reinforcing pad thickness, te:

|

|

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

The minimum required

nozzle neck thickness, as per UG-45: (For access openings and openings used

only for inspection)

|

|

|

|

mm

|

|

|

|

|

|

The minimum required

nozzle neck thickness, as per UG-45: (For other nozzles)

|

|

|

|

|

|

|

|

mm

|

|

|

| |

|

|

The Nozzle Nominal

thickness, tsn:

|

|

|

|

|

|

|

|

|

|

|

|

|

mm

|

|

|

| |

|

|

Nozzle for:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check If tr ≤ t

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check If trn ≤ tn

|

|

|

|

|

|

|

|

Without reinforcing

element

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Is the available reinforcing area of At greater than the required area of A:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With reinforcing element

added

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Is the available reinforcing area of At greater than the required area of A:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASME BPVC

VIII-1-2015, UG-45 Nozzle Neck

Thickness and,

|

|

|

|

|

|

|

|

|

|

|

|

Page

|

|

|

|

UG-37 Reinforcement

Required for Openings in Shells and Formed Heads

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Formula Data

|

|

|

|

|

|

|

|

Notes

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CA =

|

|

mm

|

|

|

|

|

|

Corrosion Allowance

|

|

|

|

|

|

|

|

|

|

|

U1 =

|

|

|

default value = 0

|

|

|

|

Shell Undertolerance

Allowance (As per UG-16(c) & UG-16(d))

|

|

|

|

|

|

|

U2 =

|

|

mm

|

|

|

|

|

|

Shell Undertolerance

Thickness

|

|

|

|

|

|

|

|

|

|

D =

|

|

mm

|

|

|

|

|

|

Shell Nominal inside Dia

|

|

|

|

|

|

|

|

|

|

|

Do =

|

|

mm

|

|

|

|

|

|

Shell Outside Dia.

|

|

|

|

|

|

|

|

| |

|

|

DH

=

|

|

mm

|

|

|

|

|

|

Head Nominal inside Dia

|

|

|

|

|

|

|

|

| |

|

|

DEH

=

|

|

mm

|

|

|

|

|

|

Ellipsoidal Head inside

Dia. with corrosion removed

|

|

|

|

|

| |

|

|

LTH

=

|

|

mm

|

|

|

|

|

|

Torispherical Head inner

diameter of the skirt adjusted for corrosion

|

|

|

|

|

|

|

d =

|

|

mm

|

(opening in Parent

Material)

|

|

|

Finished diameter of

circular opening

|

|

|

|

|

|

|

|

|

E =

|

|

|

|

|

|

|

|

Assuming E = 1.0

|

|

|

|

|

|

|

|

| |

|

|

E1

=

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F =

|

|

|

|

|

|

|

|

1.00

shall be used for all conf. except that Fig. UG-37 may be used for integrally

reinforced openings

|

| |

|

|

fr

=

|

|

|

|

|

|

|

|

Sn/Sv

|

|

|

|

|

|

|

|

|

|

| |

|

|

fr1

=

|

|

|

|

|

|

|

|

Sn/Sv for nozzle wall

inserted through the vessel wall

|

|

|

|

|

| |

|

|

fr2

=

|

|

|

|

|

|

|

|

Sn/Sv

|

|

|

|

|

|

|

|

|

|

| |

|

|

fr3

=

|

|

|

|

|

|

|

|

(lesser of Sn or Sp) / Sv

|

|

|

|

|

|

|

|

| |

|

|

fr4

=

|

|

|

|

|

|

|

|

Sp/Sv

|

|

|

|

|

|

|

|

|

|

|

|

|

h =

|

|

mm

|

default value = 0

|

|

|

|

Nozzle inside projection

|

|

|

|

|

|

|

|

| |

|

|

hH

=

|

|

mm

|

If DH > 0

|

For Nozzle welded on

Ellipsoidal Head 2:1. hH= DH/4

|

|

|

mm

|

|

| |

|

|

K =

|

|

|

|

|

|

|

|

Factor in the equations

for ellipsoidal heads, Table 1-4.1

|

|

|

|

|

| |

|

|

K1

=

|

|

|

|

|

|

|

|

Spherical radius factor

(see Table UG-37)

|

|

|

|

|

|

| |

|

|

LEH

=

|

|

mm

|

|

|

|

|

|

Inside spherical or

crown radius for ellipsoidal head, L = k1D

|

|

|

|

|

|

|

M =

|

|

|

|

|

|

|

|

Assuming M = 1.0

|

|

|

|

|

|

|

|

|

|

|

L =

|

0

|

|

|

|

|

|

|

Applicable for LWNF

only, Figure UG-40 sketch (e)

|

|

|

|

|

|

|

|

P =

|

|

bar

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Pe

=

|

|

bar

|

default value = 0

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

R =

|

|

mm

|

|

|

|

|

|

Shell Inner radius

|

|

|

|

|

|

|

|

|

| |

|

|

Rv

=

|

|

mm

|

|

|

|

|

|

Shell Inner radius with

corrosion & undertolerance removed

|

|

|

|

|

| |

|

|

Rn

=

|

|

mm

|

|

|

|

|

|

Nozzle Inner radius with

corrosion & undertolerance removed

|

|

|

|

| |

|

|

LHH

=

|

|

mm

|

|

|

|

|

|

Hemispherical Head

inside spherical or crown radius adjusted for corrosion

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Sn

=

|

|

MPa

|

Material Specification as per ASME II-D Tables

|

|

|

|

|

|

|

|

|

| |

|

|

Sp

=

|

|

MPa

|

|

|

|

|

|

|

|

|

| |

|

|

Sv

=

|

|

MPa

|

|

|

|

|

|

|

|

|

| |

|

|

T =

|

|

°C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

ts

=

|

|

mm

|

Shell Nominal Thk.

|

|

|

Nozzle welded on:

|

|

|

|

|

|

|

| |

|

|

t =

|

|

mm

|

Shell Nom. Thk. adjusted

by Tolerances

|

Head Type:

|

|

|

If Nozzle is welded on

Head

|

|

|

| |

|

|

th

=

|

|

mm

|

Head Nominal Thk. After

forming

|

|

Nozzle for:

|

|

|

|

|

|

|

|

| |

|

|

t =

|

|

mm

|

Head Nominal Thk. After

forming adjusted by tolerances

|

|

|

|

|

|

|

|

|

| |

|

|

t =

|

|

mm

|

Selected t

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

ti

=

|

|

mm

|

Nozzle Inside Proj. Thk.

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tsn

=

|

|

mm

|

Nozzle Nominal Thk.

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tn

=

|

|

mm

|

Nozzle Nominal Thk.

adjusted by tolerances

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

trs

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tre

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

trh

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

trt

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tr

=

|

|

mm

|

Selected tr

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

trn

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check If tr ≤ t

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A41

leg =

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A43

leg =

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Nozzle Neck dimensions

(ASME B36.10M & ASME B36.19M):

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pipe size (DN):

|

|

|

|

|

|

|

|

Nozzle Neck Nominal

thickness, tsn:

|

|

|

mm

|

|

|

|

|

Schedule:

|

|

|

|

|

|

|

|

Nozzle Neck thickness

undertolerance, U3:

|

|

mm

|

|

|

|

|

Approximate ID:

|

|

|

mm

|

|

|

|

|

(undertolerance = 12.5%)

|

|

|

|

|

|

|

|

|

|

Approximate OD:

|

|

|

mm

|

|

|

|

|

Nominal thickness less

'c' & 'U3', tn:

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check If trn ≤ tn

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nozzle Neck thickness trn for external

pressure as per Section VIII Div 1 - UG 28(c)

|

|

|

|

|

|

|

|

|

|

| |

|

|

trn for external pressure:

|

|

mm

|

default value = 0

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nozzle Pad details

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Dp

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

te

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A42

leg =

|

|

mm

|

default value = 0

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASME BPVC

VIII-1-2015, UG-45 Nozzle Neck

Thickness and,

|

|

|

|

|

|

|

|

|

|

|

|

Page

|

|

|

|

UG-37 Reinforcement

Required for Openings in Shells and Formed Heads

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Calculations

|

|

|

|

|

|

|

|

|

|

|

ASME VIII Reference

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

(a) Calculate limits of

reinforcement

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Parallel to vessel wall,

use larger of :

|

|

|

|

|

|

|

|

|

UG-40

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

d =

|

|

|

mm

|

|

|

|

|

|

|

|

UG-40(b)(1)

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Rn + tn

+ t =

|

|

mm

|

|

|

|

|

|

|

|

UG-40(b)(2)

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Use

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Normal to vessel wall

outside use smaller of:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

2.5t =

|

|

|

mm

|

|

|

|

|

|

|

|

UG-40(c)(1)

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

2.5tn + te =

|

|

mm

|

|

|

|

|

|

|

|

UG-40(c)(2)

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Use

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Normal to vessel wall

inside use smaller of:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

h =

|

|

|

mm

|

|

|

|

|

|

|

|

UG-40(c)(1)

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

2.5t =

|

|

|

mm

|

|

|

|

|

|

|

|

UG-40(c)(2)

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

2.5ti =

|

|

|

mm

|

|

|

|

|

|

|

|

UG-40(c)(2)

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Use

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

(b) Shell, Head and

nozzle required thickness:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

with

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

CA =

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

P =

|

|

bar

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Pe

=

|

|

bar

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

DEH

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

LTH =

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

RV

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

LHH =

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Rn

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Sv

=

|

|

MPa

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Sn

=

|

|

MPa

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

E =

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

K =

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

M =

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Required shell

thickness:

|

|

(Internal Pressure)

|

|

|

|

|

|

|

Required shell

thickness:

|

|

(External

Pressure)

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

trs =

|

PRv

|

+ CA

|

|

|

|

|

|

|

|

|

|

trs =

|

PRv

|

+ CA

|

|

|

|

|

| |

|

|

SE - 0.6P

|

|

|

|

|

|

|

|

|

|

SE - 0.6P

|

|

|

|

|

| |

|

|

trs

=

|

|

mm

|

|

|

|

|

|

|

|

|

trs

=

|

|

mm

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Required ellipsoidal

head thickness:

|

(Internal Pressure)

|

|

|

|

|

|

|

Required ellipsoidal

head thickness:

|

(External

Pressure)

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tre =

|

PDEHK

|

+ CA

|

|

|

|

|

|

|

|

|

|

tre =

|

PDEHK

|

+ CA

|

|

|

|

|

| |

|

|

2SE - 0.2P

|

|

|

|

|

|

|

|

|

|

2SE - 0.2P

|

|

|

|

|

| |

|

|

tre

=

|

|

mm

|

|

|

|

|

|

|

|

|

tre

=

|

|

mm

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Required hemispherical

head thickness:

|

(Internal Pressure)

|

|

|

|

|

|

|

Required hemispherical

head thickness:

|

(External

Pressure)

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

trh =

|

PLHH

|

+ CA

|

|

|

|

|

|

|

|

|

|

trh =

|

PLHH

|

+ CA

|

|

|

|

|

| |

|

|

2SE - 0.2P

|

|

|

|

|

|

|

|

|

|

2SE - 0.2P

|

|

|

|

|

| |

|

|

trh

=

|

|

mm

|

|

|

|

|

|

|

|

|

trh

=

|

|

mm

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Required torispherical

head thickness:

|

(Internal Pressure)

|

|

|

|

|

|

|

Required torispherical

head thickness:

|

(External

Pressure)

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

trt =

|

PLTHM

|

+ CA

|

|

|

|

|

|

|

|

|

|

trt =

|

PLTHM

|

+ CA

|

|

|

|

|

| |

|

|

2SE - 0.2P

|

|

|

|

|

|

|

|

|

|

2SE - 0.2P

|

|

|

|

|

| |

|

|

trt

=

|

|

mm

|

|

|

|

|

|

|

|

|

trt

=

|

|

mm

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Required nozzle neck

thickness:

|

(Internal Pressure)

|

|

|

|

|

|

|

Required nozzle neck

thickness:

|

(External

Pressure)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

As per Section VIII Div

1 - UG 28(c) - Thickness of Shells

|

|

|

|

|

trn =

|

PRn

|

+ CA

|

|

|

|

|

|

|

|

|

|

and Tubes under External

Pressure

|

|

|

|

| |

|

|

SE - 0.6P

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

trn

=

|

|

mm

|

|

|

|

|

|

|

|

|

trn

=

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

ASME BPVC

VIII-1-2015, UG-45 Nozzle Neck

Thickness and,

|

|

|

|

|

|

|

|

|

|

|

|

Page

|

|

| |

|

UG-37 Reinforcement

Required for Openings in Shells and Formed Heads

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

(c) Determine required

replacement area:

|

|

|

|

|

|

|

|

|

Notes

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A =

|

d tr

F + 2tn tr F(1 - fr1)

|

|

|

|

|

|

|

|

|

|

Ref: UG-37 (C)- Design

for Internal Pressure.

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A =

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

(d) Calculate area

contributions:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Area available in the

vessel wall, use larger value:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A1.1 =

|

d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A1.1 =

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A1.2 =

|

2(t + tn)(E1t - Ftr) - 2tn(E1t - Ftr)(1 - Fr1)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A1.2 =

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Use A1 =

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Area available in nozzle

projecting outward, use smaller value:

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

With reinforcing element

added

|

|

|

|

|

|

|

|

|

|

Without reinforcing

element

|

|

|

|

|

| |

|

|

A2.1 =

|

5(tn - trn)(fr2)(t)

|

|

|

|

|

|

|

|

|

|

A2.1 =

|

5(tn - trn)(fr2)(t)

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A2.1 =

|

|

|

mm2

|

|

|

|

|

|

|

|

A2.1 =

|

|

|

mm2

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

With reinforcing element

added

|

|

|

|

|

|

|

|

|

|

Without reinforcing

element

|

|

|

|

|

| |

|

|

A2.2 =

|

2(tn - trn)(2.5tn + te)(fr2)

|

|

|

|

|

|

|

|

|

A2.2 =

|

5(tn - trn)(fr2)(tn)

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A2.2 =

|

|

|

mm2

|

|

|

|

|

|

|

|

A2.2 =

|

|

|

mm2

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Use A2 =

|

|

mm2

|

|

|

|

|

|

|

|

Use A2 =

|

|

mm2

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Area available due to

inward projection of nozzle, use smaller value:

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A3.1 =

|

5t ti fr2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A3.1 =

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A3.2 =

|

5ti

ti fr2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A3.2 =

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A3.3 =

|

2h ti fr2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A3.3 =

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Use A3 =

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

ASME BPVC

VIII-1-2015, UG-45 Nozzle Neck

Thickness and,

|

|

|

|

|

|

|

|

|

|

|

|

Page

|

|

| |

|

UG-37 Reinforcement

Required for Openings in Shells and Formed Heads

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Area available in welds:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

with reinforcing element

added

|

|

|

|

|

|

|

|

|

|

Without reinforcing

element

|

|

|

|

|

| |

|

|

A41

=

|

(leg)2 fr3

|

|

Outward Nozzle Weld

|

|

|

|

|

|

|

A41

=

|

(leg)2 fr2

|

|

Outward Nozzle Weld

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A41

=

|

|

|

mm2

|

|

|

|

|

|

|

|

A41

=

|

|

|

mm2

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A42

=

|

(leg)2 fr4

|

|

Outer Element/Pad Weld

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A42

=

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A43

=

|

(leg)2 fr2

|

|

Inward Nozzle Weld

|

|

|

|

|

|

|

A43

=

|

(leg)2 fr2

|

|

Inward Nozzle Weld

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A43

=

|

|

|

mm2

|

|

|

|

|

|

|

|

A43

=

|

|

|

mm2

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Area in reinforcing pad:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A5

=

|

(Dp - d - 2tn)te fr4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

A5

=

|

|

|

mm2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

(e) Total area

available:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

With reinforcing element

added

|

|

|

|

|

|

|

|

|

|

Without reinforcing

element

|

|

|

|

|

| |

|

|

At

=

|

A1 + A2 + A3 + A41 + A42 + A43 + A5

|

|

|

|

|

|

|

|

At

=

|

A1 + A2 + A3 + A41 + A43

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

At

=

|

|

mm2

|

|

|

|

|

|

|

|

|

At

=

|

|

mm2

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

At

=

|

|

mm2

|

|

|

mm2

|

|

|

(A)

|

|

|

|

At

=

|

|

mm2

|

|

|

mm2

|

(A')

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Is the available

reinforcing area of At is

|

|

|

|

|

|

|

|

|

Is the available

reinforcing area of At is

|

|

|

|

| |

|

|

greater than the

required area of A:

|

|

|

|

|

|

|

|

|

greater than the

required area of A:

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

ASME BPVC

VIII-1-2015, UG-45 Nozzle Neck

Thickness and,

|

|

|

|

|

|

|

|

|

|

|

|

Page

|

|

| |

|

UG-37 Reinforcement

Required for Openings in Shells and Formed Heads

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

(g) Check nozzle neck

thickness as specified in UG-45.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

For access openings and

openings used only for inspection:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tUG-45 = ta

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

For all nozzles other

than access openings and openings used only for inspection, determine tb:

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tb = min[tb3, max(tb1, tb2)]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

tUG-45 = max(ta, tb)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

where

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

ta

=

|

minimum neck

thickness required for internal and external pressure using UG-27 and UG-28

(plus corrosion allowance),

|

|

| |

|

|

as applicable.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

tb1

=

|

for vessels under

internal pressure, the thickness (plus corrosion allowance) required for

pressure (assuming

|

|

|

|

|

|

|

|

| |

|

|

E = 1.0) for the shell

or head at the location where the nozzle neck or other connection attaches to

the vessel.

|

|

|

|

|

|

|

|

| |

|

tb2

=

|

for vessels under

external pressure, the thickness (plus corrosion allowance) obtained by using

the external

|

|

|

|

|

|

|

|

|

| |

|

|

design pressure as an

equivalent internal design pressure (assuming E = 1.0) in the formula for the

shell or

|

|

|

|

|

|

|

|

|

| |

|

|

head at the location

where the nozzle neck or other connection attaches to the vessel.

|

|

|

|

|

|

|

|

|

|

|

| |

|

tb3

=

|

the thickness given in

Table UG-45 plus the thickness added for corrosion allowance.

|

|

|

|

|

|

|

|

|

|

|

| |

|

tUG-45 =

|

minimum wall thickness

of nozzle necks

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

DN =

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

| |

|

trn

=

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

ta

=

|

|

|

|

|

mm

|

|

|

|

|

|

|

trn with corrosion and undertolerance removed

|

|

|

| |

|

tb1

=

|

|

|

|

|

mm

|

|

|

|

|

|

|

tr with corrosion and undertolerance removed

|

|

|

| |

|

tb2

=

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

tb3

=

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

tb

=

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

For access openings and

openings used only for inspection:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Minimum Nozzle Neck

Thickness required, tUG-45 = ta

|

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|